In the century-long craze of carbon peak and carbon neutrality, countries around the world are actively looking for the next generation of energy technology, and green ammonia is becoming the focus of global attention recently. Compared with hydrogen, ammonia is expanding from the most traditional agricultural fertilizer field to the energy field due to its obvious advantages in storage and transportation.

Faria, an expert at the University of Twente in the Netherlands, said that with the rise in carbon prices, green ammonia may be the future king of liquid fuels.

So, what exactly is green ammonia? What is its development status? What are the application scenarios? Is it economical?

Green ammonia and its development status

Hydrogen is the main raw material for ammonia production. Therefore, according to the different carbon emissions in the hydrogen production process, ammonia can also be classified into the following four categories by color:

Gray ammonia: Made from traditional fossil energy (natural gas and coal).

Blue ammonia: Raw hydrogen is extracted from fossil fuels, but carbon capture and storage technology is used in the refining process.

Blue-green ammonia: The methane pyrolysis process decomposes methane into hydrogen and carbon. The hydrogen recovered in the process is used as raw material to produce ammonia using green electricity.

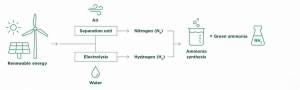

Green ammonia: Green electricity generated by renewable energy such as wind and solar energy is used to electrolyze water to produce hydrogen, and then ammonia is synthesized from nitrogen and hydrogen in the air.

Because green ammonia produces nitrogen and water after combustion, and does not produce carbon dioxide, green ammonia is considered a “zero-carbon” fuel and one of the important clean energy sources in the future.

The global green ammonia market is still in its infancy. From a global perspective, the green ammonia market size is about US$36 million in 2021 and is expected to reach US$5.48 billion in 2030, with an average annual compound growth rate of 74.8%, which has considerable potential. Yundao Capital predicts that the global annual production of green ammonia will exceed 20 million tons in 2030 and exceed 560 million tons in 2050, accounting for more than 80% of the global ammonia production.

As of September 2023, more than 60 green ammonia projects have been deployed worldwide, with a total planned production capacity of more than 35 million tons/year. Overseas green ammonia projects are mainly distributed in Australia, South America, Europe and the Middle East.

Since 2024, the domestic green ammonia industry in China has developed rapidly. According to incomplete statistics, since 2024, more than 20 green hydrogen ammonia projects have been promoted. Envision Technology Group, China Energy Construction, State Power Investment Corporation, State Energy Group, etc. have invested nearly 200 billion yuan in promoting green ammonia projects, which will release a large amount of green ammonia production capacity in the future.

Application scenarios of green ammonia

As a clean energy, green ammonia has a variety of application scenarios in the future. In addition to traditional agricultural and industrial uses, it also mainly includes blending power generation, shipping fuel, carbon fixation, hydrogen storage and other fields.

1. Shipping industry

Carbon dioxide emissions from shipping account for 3% to 4% of global carbon dioxide emissions. In 2018, the International Maritime Organization adopted a preliminary strategy for greenhouse gas emission reduction, proposing that by 2030, global shipping carbon emissions will be reduced by at least 40% compared with 2008, and strive to reduce by 70% by 2050. In order to achieve carbon reduction and decarbonization in the shipping industry, clean fuels replacing fossil energy is the most promising technical means.

It is generally believed in the shipping industry that green ammonia is one of the main fuels for decarbonization in the shipping industry in the future.

Lloyd’s Register of Shipping once predicted that between 2030 and 2050, the proportion of ammonia as shipping fuel will increase from 7% to 20%, replacing liquefied natural gas and other fuels to become the most important shipping fuel.

2. Power generation industry

Ammonia combustion does not produce CO2, and ammonia-mixed combustion can utilize existing coal-fired power plant facilities without major modifications to the boiler body. It is an effective measure for reducing carbon dioxide emissions in coal-fired power plants.

On July 15, the National Development and Reform Commission and the National Energy Administration issued the “Action Plan for Low-carbon Transformation and Construction of Coal Power (2024-2027)”, which proposed that after transformation and construction, coal power units should have the ability to blend more than 10% of green ammonia and burn coal. Consumption and carbon emission levels are significantly reduced. It can be seen that mixing ammonia or pure ammonia in thermal power units is an important technical direction for carbon emission reduction in the power generation field.

Japan is a major promoter of ammonia blended combustion power generation. Japan formulated the “2021-2050 Japan Ammonia Fuel Roadmap” in 2021, and will complete the demonstration and verification of 20% blended ammonia fuel in thermal power plants by 2025; as the ammonia blended technology matures, this proportion will increase to more than 50%; by around 2040, a pure ammonia power plant will be built.

3. Hydrogen storage carrier

Ammonia is used as a hydrogen storage carrier, and needs to go through the processes of ammonia synthesis, liquefaction, transportation, and re-extraction of gaseous hydrogen. The whole process of ammonia-hydrogen conversion is mature.

At present, there are six main ways of hydrogen storage and transportation: high-pressure cylinder storage and transportation, pipeline gaseous pressurized transportation, low-temperature liquid hydrogen storage and transportation, liquid organic storage and transportation, liquid ammonia storage and transportation, and metal solid hydrogen storage and transportation. Among them, liquid ammonia storage and transportation is to extract hydrogen through ammonia synthesis, liquefaction, transportation, and regasification. Ammonia is liquefied at -33°C or 1MPa. The cost of hydrogenation/dehydrogenation accounts for more than 85%. It is not sensitive to transportation distance and is suitable for medium and long-distance storage and transportation of bulk hydrogen, especially ocean transportation. It is one of the most promising ways of hydrogen storage and transportation in the future.

4. Chemical raw materials

As a potential green nitrogen fertilizer and the main raw material for green chemicals, green ammonia will strongly promote the rapid development of the “green ammonia + green fertilizer” and “green ammonia chemical” industrial chains.

Compared with synthetic ammonia made from fossil energy, it is expected that green ammonia will not be able to form effective competitiveness as a chemical raw material before 2035.

Post time: Aug-09-2024